Ultrasonic inspection is defined as a non-destructive inspection procedure of mechanical type and its operation is based on acoustic impedance, which is manifested as the product of the maximum velocity of sound propagation and the density of the material. It uses a single device that functions as an emitter and receiver, based on the characteristic property of the sound to be reflected when reaching an acoustic interface.

By means of the ultrasound technique, we detect any type of internal lack of continuity that could be housed in the material. Our equipment has self-evaluation software which helps to make a more accurate decision regarding material findings.

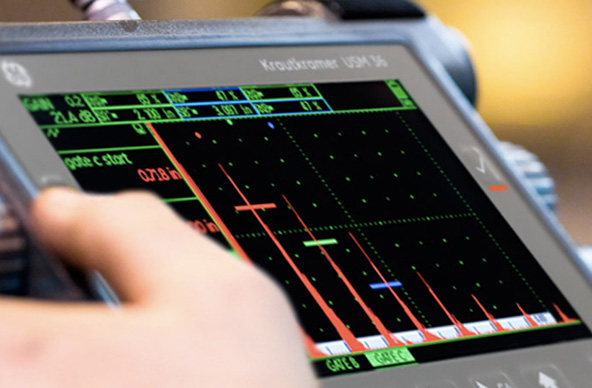

Detector de fallas

EQUIPO DE ULTRASONIDO CONVENCIONAL

In the case of (Phased Array) there is a greater definition and resolution of the defect than with conventional fault detection equipment, having the option of dimensioning and locating in a more precise way the discontinuities, giving us a greater advantage than the conventional ultrasound equipment. We have "encoder" that allows us to generate the complete records of these inspections.

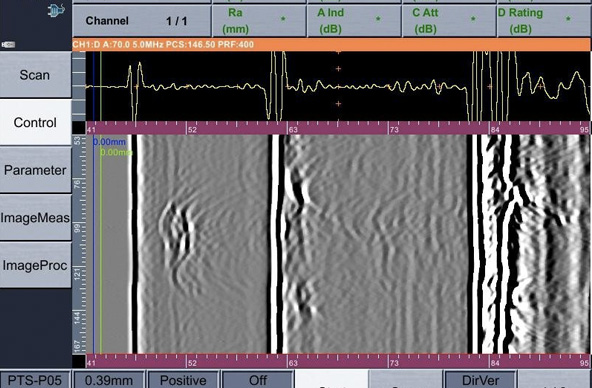

The TOFD (Time of flight diffraction) automated test is a powerful tool for welding inspection, widely used worldwide in the mining, nuclear and petrochemical sector.

The technique allows a very fast and efficient quality control to welds of great thickness, or with complex bevel configurations, where the technique P-E or PAUT can have problems.

The TOFD technique detects discontinuities regardless of orientation, however it has 2 dead zones, so the test must be combined with ultrasonic techniques such as conventional UT, UT PE machining or Phased array.

TOFD ULTRASOUND EQUIPMENT

Ultrasonic thickness measurement is a non-destructive test technique for which it is not necessary to cut or section the material. It is a fast, reliable and versatile method that unlike the use of a micrometer or a gauge, requires access to only one wall of the piece to be measured. It is therefore widely used to determine the thickness of materials such as pipes, tubes, valves, tanks, boilers and other pressure vessels, naval shells or any material subject to corrosion and wear.

US thickness measurement / SIUI CTS-59

Equipo medición de espesores ultrasónico